What is the F1 Car Skid Block (Plank)?

Technical Analysis of the F1 Skid Block: How the 1 mm Wear Limit Influences Aerodynamics, Set-up, and Infamous Disqualifications (Like the McLaren Case)

The Plank (or skid block) is the rigid laminated strip made of composite (phenolic) material fitted to the central underside of the F1 car. Introduced in 1994 as a safety measure to limit ground effect and speeds, it is now the barometer for extreme aerodynamic set-ups.

The rule is absolute: the plank, which initially measures 10 mm in thickness, cannot fall below 9 mm at the control points designated by the FIA. This 1 mm wear tolerance is the fine line between legality and disqualification.

The recent case of McLaren, disqualified for excessive wear of the plank, has put a spotlight back on this component. Exceeding the limit, even by fractions of a millimeter, is proof that the car was run at a more aggressive ride height than permitted, obtaining a direct advantage in terms of downforce generated by the floor.

Primary (Regulatory) Function

The skid block was introduced in 1994, following the Imola weekend accidents, as a safety measure to limit the minimum ride height of the cars. It prevents teams from running the single-seaters too low to maximize the downforce generated by the floor (ground effect), which would make the car dangerously sensitive to variations in the track surface and attitude.

What it’s Made of: Skid Block and Skid Plates

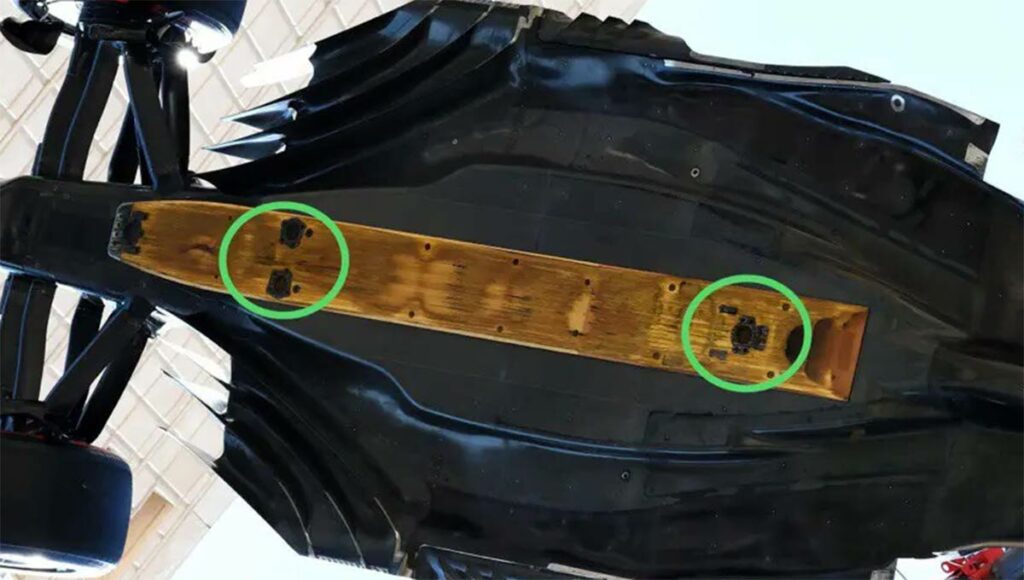

The skid block consists of a larger central board. Skid Plates are inserts (or blocks, often made of titanium or high-strength alloys) embedded in the plank, at the measurement points or in strategic areas. When the car scrapes the asphalt, it is these inserts (often responsible for the spectacular sparks) that wear down first, partially protecting the composite material of the plank.

The main plank is made of a lightweight composite material (generally glass-based resin), which would wear down quickly. Protecting it from extreme abrasion are inserts and plates, called skid plates, made of titanium alloy (or zirconium). It is these titanium blocks, embedded in the plank, that produce the spectacular sparks when the car “scrapes” the asphalt (bottoming).

Skid Block and F1 Technical Regulations

The Formula 1 technical regulations clearly establish the specifications and wear limits of the skid block, aiming to ensure the single-seater maintains a certain ride height and structural rigidity.

Thickness and Wear Requirements

The key point of the regulation concerns the minimum permitted plank thickness.

- Initial Thickness: The plank thickness at the start of the race (or a qualifying session) must be 10 mm (+/- 0.2 mm).

- Wear Limit: At the end of the race or session, at specific measurement points designated by the FIA, the plank thickness must not be less than 9 mm. This means the maximum permitted wear is 1 mm at those points.

- Measurement Points: The FIA takes measurements at predefined holes in the plank, around which the titanium skid blocks are positioned.

Violation and Disqualification

Violation of the plank wear rule is considered an absolute technical infringement (non-conformity).

- Consequence: If, at the end of post-race scrutineering, it is found that the plank thickness at any of the measurement points is less than 9 mm, disqualification is automatic and unavoidable. There are no alternative penalties (such as time penalties or grid demotions).

- Rationale: This rigidity is due to the fact that excessive wear indicates the car ran at a ride height below the regulatory minimum for a significant time, thereby obtaining a potentially illicit aerodynamic advantage.

The McLaren Case (and Precedents)

The disqualification of the McLarens (for example, at the Las Vegas GP 2025, or previous cases like Leclerc and Hamilton at Austin 2023) occurred precisely for this reason: excessive plank wear.

The technical stewards found that the plank thickness was below the 9 mm minimum limit at some measurement points (e.g., “RHS FRONT 8.88 mm”).

Teams often attribute excessive wear to external factors, such as bumps or unpredicted or uncontrollable porpoising (vertical oscillation) under certain conditions. However, the technical regulation is clear: conformity is the team’s responsibility at all times during the session.

FIA Conformity Verification

The FIA takes measurements at four designated holes strategically placed along the plank. Two holes are located at the front and two at the rear of the plank. The stewards measure the remaining thickness of the plank at the perimeter of these holes.

By measuring around these titanium inserts, the FIA ensures they check the point of the floor that has been closest to the ground and designed to withstand maximum stress. If the plank thickness is less than 9 mm at any of these four points, disqualification is automatic.

Proposed Material Change: Titanium vs. Steel

The FIA has proposed and discussed the possibility of replacing the titanium of the skid plates with stainless steel. The main reason for the potential material change is not related to regulatory wear, but to safety and, specifically, the risk of fire.

Titanium sparks tend to be brighter, hotter, and have greater thermal inertia; meaning they can retain heat and remain “lit” longer after contact with the asphalt. When a car scrapes titanium near dry grass or trackside debris, the sparks can easily ignite a fire, especially at circuits with high ambient temperatures.

The FIA has acknowledged the fire risk issue. However, at present, the Federation has confirmed that the skid blocks remain titanium (as they are more efficient and lighter) but has required teams to develop and bring the steel alternative to the track as a backup, to be deployed immediately in selected races (or where conditions require it) to mitigate the fire risk.

Performance Impact (Aerodynamic Context)

Ride height is crucial for modern ground effect F1 cars:

- Maximising Ground Effect: The closer the car’s floor is to the asphalt, the more the Venturi tunnel under the car can be “sealed,” increasing the airflow speed.

- Increased Downforce: This increase in flow speed generates much greater downforce, which pushes the car down, improving grip and cornering speed.

- The Compromise: Teams try to set the ride height at the absolute minimum limit to maximize performance, while knowing they risk excessive plank wear leading to disqualification. It is a delicate compromise between speed and legality.

Skid Block and Downforce

The impact of skid block wear is inextricably linked to the principle of Ground Effect, the main source of downforce for the modern single-seaters introduced in 2022.

The Critical Role of Ride Height (h)

Ground effect is generated by the tunnels (Venturi channels) running under the car. To maximize downforce:

- The maximum “vacuum” (depression) must be created under the car.

- This is achieved by accelerating the airflow at the narrowest point between the car floor and the asphalt (the “throat”).

The amount of downforce generated is extremely sensitive to small variations in ride height:

- Non-Linear Relationship: Aerodynamic load (Cl) increases non-linearly (exponentially) as “h” decreases, up to an optimal point.

- 1 mm Margin: In the maximum ground effect exploitation zone, a set-up reduction of even a single millimeter can lead to a significant increase in downforce, which translates into higher cornering speed and, thus, a faster lap time.

The Skid Block as a Limiter for Height “h”

The technical regulation (9 mm plank thickness) is the mechanism the FIA uses to indirectly impose a minimum ride height on the single-seater.

- Aggressive Set-up: To obtain maximum downforce, engineers set the car up so that the floor travels as close as possible to the asphalt, accepting that the skid block will scrape and wear down throughout the race.

- Maximum Permitted Wear: The 1 mm wear limit (from 10 mm to 9 mm) represents the maximum a team can “exploit” to gain the advantage of a reduced ride height.

Practical Example of the Advantage

Let’s assume, as an example, that:

- Legal Configuration (Margin): A car is set up to finish the race with 0.5 mm of plank wear. This means it has run with a certain safety margin for wear.

- Illegal Configuration (Disqualification): A McLaren car was set up more aggressively, hoping for 1 mm of wear, but due to excessive porpoising, bumps, or a set-up calibration error, it finished with 1.12 mm of wear (i.e., the plank is 0.12 mm below the limit).

That tiny 0.12 mm of excessive wear (which leads to disqualification) indicates that, on average, the car travelled for most of the race at a lower ride height than permitted.

This lowering, even if measured in tenths of a millimeter:

- Increases V max: Allows the Venturi channels to be better sealed, leading to greater depression and thus more downforce.

- Improves Efficiency: This downforce is generated with minimal impact on drag, making the car extremely efficient.

In summary, the team that manages to run the car at the maximum wear limit (just under 1 mm) gains a significant performance advantage compared to those using a more cautious set-up. Exceeding that limit, even by a tiny amount (as in the McLaren case where measurements were $8.88 \text{ mm}$ and $8.93 \text{ mm}$), means the aerodynamic advantage gained was excessive and technically illicit, leading to immediate disqualification according to the F1 Technical Regulations (Article 3.5.9).

Suspension Stiffness and Plank Wear

Yes, the wear of the skid block is closely linked to track conditions (like rain) and suspension tuning, and teams work at the limit of these factors.

Rain, “Lubrication,” and Plank Wear

One might think that with rain, water could “lubricate” and reduce skid block wear: this is intuitively correct but the main effect is much more complex and aerodynamic.

When it rains, drivers must drastically reduce speed, especially in corners, due to the poor grip of wet tires. The downforce generated by the wing and especially the floor is proportional to the square of the speed. With a much lower speed, the total downforce significantly decreases. Since the car intrinsically runs higher and with less load pushing it onto the asphalt, in theory, plank wear should be lower in wet track conditions.

Rigidity of the Suspension and Plank Wear

The most critical factor for plank wear in any condition (dry or wet) is the set-up stiffness (suspension, anti-roll bars, dampers).

The Rigid Aerodynamic Platform

Modern ground effect single-seaters require an extremely rigid aerodynamic platform (case stiffness), which is achieved with very hard suspensions:

- Objective: The suspension must resist the immense forces generated by downforce (which presses the car down) and keep the floor and diffuser at a constant and lowest possible ride height (h) (in the millimeter range) to maximize the ground effect.

- Bottoming (Scraping): Stiffness is used to minimize vertical movements (oscillation, roll, and pitch, known as transients) that would cause the floor to lift or lower unpredictably, interrupting the airflow.

The Link to Wear

A rigid suspension is essential for maximum aerodynamic performance but carries the risk of violent bottoming:

- Limit Set-up: Teams choose a ride height and stiffness such that, under full aerodynamic load and at high speed, the car “lightly scrapes” the asphalt, wearing the plank down to the 1 mm limit.

- Unforeseen Factors: Factors such as tire wear, fuel drop (which lightens the car), curbs, or track bumps can cause the car to drop more than expected, leading to excessive wear (greater than 1 mm).

- Disqualification Case: If the set-up is too rigid and the height is too low for the actual track conditions, wear will exceed the 9 mm residual limit, and disqualification will be the direct result of a too aggressive mechanical/aerodynamic set-up.

Stiffness is crucial in the dry, where it is calibrated to bring the plank exactly to the 1 mm wear limit.